Paint Correction & Ceramic Coating at American Dent Specialists

August 25, 2020

Understanding the Ceramic Coating Process

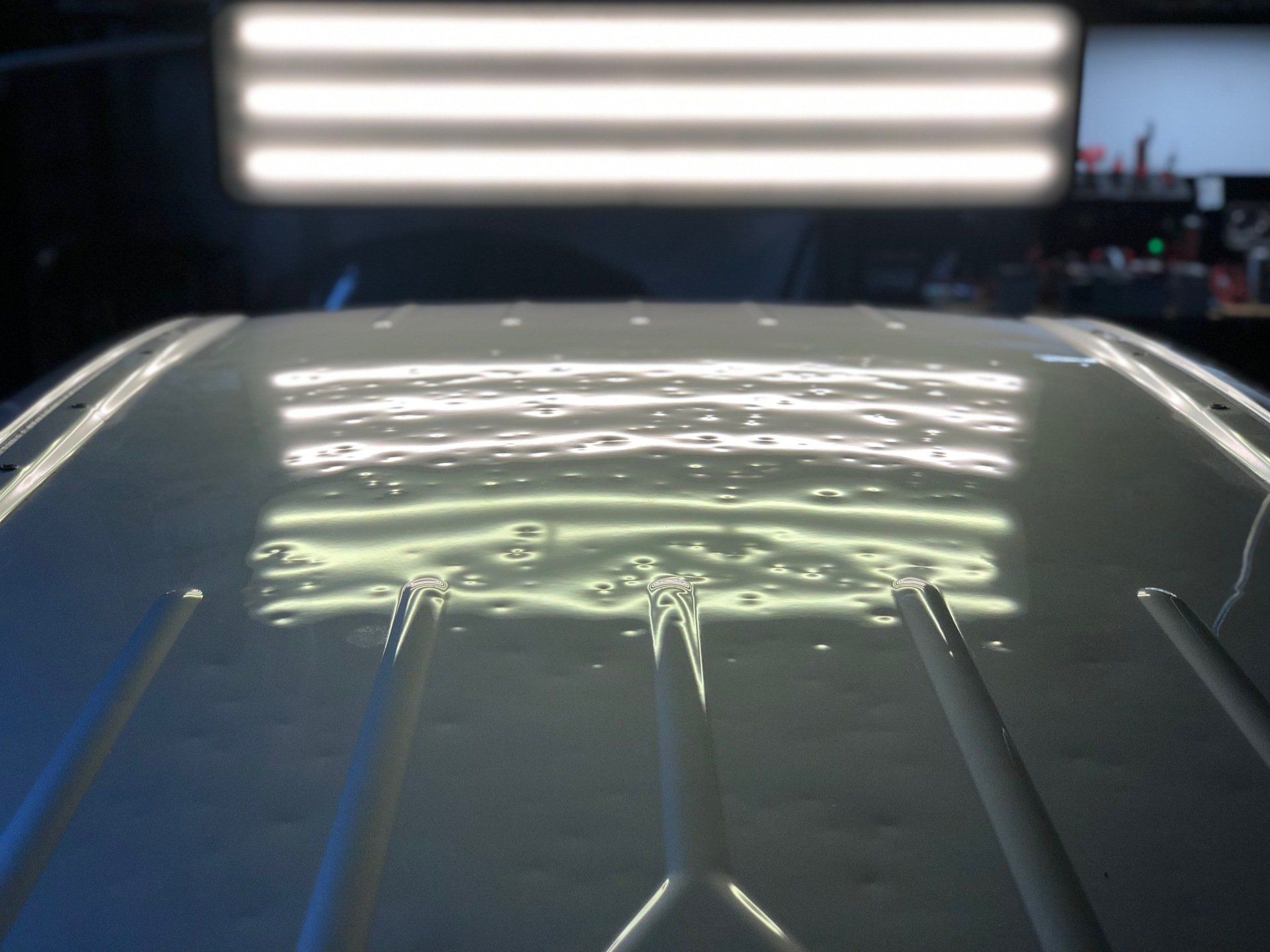

In preparation of the paint correction process, each vehicle that arrives here at American Dent Specialists receives a decontamination foam bath. Once dry, the vehicle is ready for the paint correction process to begin. First all plastic, rubber seals, and any trim pieces are taped off to ensure a contamination free process is achieved. Once this step is complete, we begin with a test area on the vehicle to determine what is necessary to restore the paint to pristine condition. Not all paint is the same. A black paint job on a BMW greatly varies when compared to say a black paint job on a Ram Truck. This testing procedure allows us to tailor our paint correction to your vehicle’s needs.

Now the actual paint correction work begins. We work from the top down to maintain the integrity of our work as we go. The first step of this process is cutting. This removes the large defects and swirl marks from the paint. Next is the refining process which further smooths and eliminates defects and swirl marks from the surface. The final step is the polishing stage. This step creates the ultimate, mirror-like shine on the surface of your vehicle. Now that the vehicle has been restored to better than factory condition, we can move to preparation for Ceramic Pro coating.

We follow the same procedure when progressing through the coating process as we do during paint correction in order to continue to maintain the integrity of our work. The workspace during the ceramic coating process is a dust free environment inside of a climate-controlled shop allowing for Houston’s #1 Ceramic Pro Coating to be applied to perfection. In the first step of preparation for Ceramic Pro coating we go over the entire vehicle with a decontamination wipe to ensure all oils or residues that could have been left over from the paint correction process have been removed leaving us with a pristine surface to coat. Then the coating process can begin. Depending on the Ceramic Pro package selected, multiple layers of our industry-leading, top-quality nanoceramic surface protection coating are applied. Once coating has been applied, the curing process starts. All of our ceramic coated vehicles are properly cured under UV lighting for the Ceramic Pro standard time frame. Upon customer arrival, we embark upon a comprehensive walk-through showcasing the videos and photos of the entire process so that the customer has a full understanding of how their vehicle was restored and is now protected. We provide detailed after care instructions and schedule their first maintenance detail for their newly coated vehicle.

Our professionally installed Ceramic Pro coating significantly increases the durability of your vehicles surface creating greater protection for your vehicle. The coating is essentially tiny particles that form a permanent bond to the surface of your paint increasing the surface tension which creates extreme hydrophobic effect. Dirt, mud, road debris, and grime will slide off of your vehicle’s surface.

Share This Blog

Austin, Texas experience a significant hail event recently. Our twenty years of pdr, hail damage repair experience means we are here to help with Austin hail damage repair too. If you have kids in the Austin area, travel to Austin to business or were there on a trip and were affected by the Austin hail storm, give us a call.

A hailstorm can cause lots of hail damage to homes, buildings and vehicles. Your safety is the most important thing during a hailstorm! The Insurance Institute of Business and Home Safety has some great tips for staying safe during a hailstorm. After the storm, we are here to repair your hail damage.